Unlocking the Power of Temperature Control

In various industrial processes, precise temperature control is not just a convenience; it's a necessity. That's where the versatile tools known as drum heater blankets and heating jackets for drums come into play. These essential devices ensure that temperature-sensitive materials stored in drums remain at the optimal temperature, even in the most challenging environments. In this article, we'll delve deep into these solutions, exploring how they work, their benefits, and the industries that rely on them.

Understanding Drum Heater Blankets and Drum Heating Jackets

A drum heater blanket, also referred to as a drum heating jacket, is an innovative device designed to maintain precise temperatures inside drums. They come equipped with a fixed internal thermostat or an adjustable thermostat that ensures your temperature-sensitive products are protected against the coldest days. A popular heating option in the past was silicone band heaters that cover a center portion of the drum, but newer drum heaters cover the entire surface of the drum, providing consistent and efficient heating.

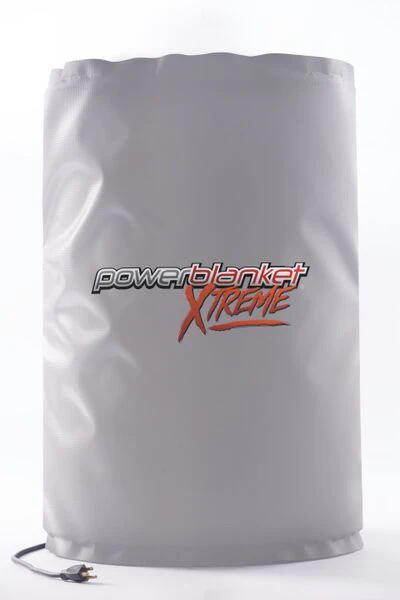

These drum heaters offer an insulated full-wrap design akin to an outer layer for your industrial drums. This innovation is akin to a warm winter coat for your drums, effectively insulating the entire drum against the cold. These jackets, including renowned options like Powerblanket drum heaters, significantly reduce power consumption and offer remarkable viscosity control for temperature-sensitive products, ensuring that materials remain at optimal viscosity.

Industries That Benefit from These Solutions

Several industries heavily rely on drums for storage and transportation. These industries span from the chemical industry and food production to pharmaceuticals, cosmetics, oil and gas, and manufacturing. In each of these sectors, maintaining precise temperatures is critical to ensuring product quality, safety, and efficiency.

Industry Examples

Let's delve into some real-world success stories to illustrate the practical benefits of drum heater blankets and heating jackets. These case studies span various industries and showcase how these heating solutions have helped companies overcome challenges and maintain precise temperature control.

Industry Study 1: Drum Heating Jackets in Food and Beverage Manufacturing

Industry: Food and Beverage Manufacturing

Challenge: Maintaining Viscosity for Precise Pouring

Solution: Drum Heating Jackets

Background:

In the food and beverage industry, maintaining the ideal viscosity of various ingredients is crucial for quality control and production efficiency. One particular challenge faced by a food and beverage manufacturing company was the storage of oils, honey, and other ingredients in large drums. These ingredients need to be heated to maintain the desired viscosity for precise pouring and mixing in the production process.

The Problem:

During colder months, the temperature-sensitive ingredients stored in drums often became too viscous, making them challenging to work with. This not only slowed down production but also risked compromising the quality of the final products.

The Solution:

The company opted for drum heating jackets, which provided an effective and efficient solution to their problem. These insulated jackets were easy to install and could be customized to fit different drum sizes. Equipped with adjustable thermostats, the jackets allowed precise temperature control.

Results:

With the drum heating jackets in place, the company successfully maintained the optimal temperature for their ingredients throughout the year. This not only improved production efficiency but also ensured the consistent quality of their food products. As a bonus, the reduced power consumption of the heating jackets translated to cost savings, making it a win-win solution for their business.

Industry Study 2: Drum Heater Jackets in Construction for Oil, Grease, and Lubrication

Industry: Construction

Challenge: Maintaining Lubricants in Cold Weather

Solution: Drum Heating Jackets

Background:

In the construction industry, heavy machinery and equipment heavily rely on lubricants, oils, and grease to function smoothly. However, during the colder months, these essential fluids often became too thick to effectively lubricate machinery, leading to potential breakdowns and delays in construction projects.

The Problem:

Construction companies faced the challenge of keeping lubricants and oils at the right viscosity for their machinery to operate optimally, even in freezing temperatures. Traditional methods like using external heaters were inefficient and costly.

The Solution:

To combat this issue, construction companies turned to drum heating jackets. These jackets provided an innovative solution for maintaining the viscosity of oils, grease, and lubricants stored in drums. They offered full coverage insulation and were designed to fit standard drum sizes. Additionally, the adjustable thermostats allowed construction crews to maintain the perfect temperature for their specific needs.

Results:

The adoption of drum heating jackets in the construction industry proved to be a game-changer. Construction projects could proceed smoothly, even during the coldest days, as machinery remained well-lubricated and efficient. The jackets also helped reduce downtime and maintenance costs associated with machinery breakdowns caused by cold weather. This not only improved productivity but also saved valuable resources for construction companies, making the investment in drum heating jackets highly worthwhile.

Benefits of Tailored Solutions

One size does not fit all when it comes to temperature control. That's why customized heating solutions like drum heater blankets and heating jackets are invaluable. These tailored solutions cater to your specific needs, ensuring thermal efficiency and cost-effectiveness. By investing in the right heating solution, businesses can enjoy substantial savings and optimal temperature maintenance. With various sizes on the market, from 15-gallon drum heating blankets to 55-gallon drum heating blankets, you can address your specific freeze protection needs.

Choosing the Right Solution for Your Needs

Selecting between drum heater blankets and drum heating jackets requires careful consideration. Your choice should depend on factors such as the type of product, the industry you operate in, the material of your drum (poly and steel drums), and your budget constraints. Making the right decision ensures that you have an effective and efficient heating solution in place.

Installation and Maintenance Tips

Proper installation and maintenance are paramount to the longevity and effectiveness of your heating solutions. Follow industry best practices, ensure safety measures are in place, and regularly inspect and maintain your drum heater blankets or heating jackets to prevent any issues.

Embracing Precision: The Future of Industrial Drum Heating

In conclusion, the world of industrial temperature control is vast, and the need for precision is ever-present. Drum heater blankets and heating jackets play pivotal roles in ensuring that products stored in drums maintain their quality, even in the harshest conditions. From the chemical industry or construction to food production and beyond, these solutions provide the means to combat cold weather, prevent materials from freezing, and maintain efficient operations.

Whether you opt for the full coverage of insulated drum heating jackets or the targeted warmth of drum heater blankets, remember that these solutions are your allies in temperature-sensitive industries. By harnessing the power of heat, you can safeguard your materials, reduce costs, and keep your operations running smoothly, even on the coldest days.